APM Automation Solutions Ltd manufacturers electronic measurement devices.

The company develops and produces instruments for measuring volume levels and three dimensional services in a variety of industrial applications.

APM has served customers worldwide.

Click here to see a video presentation on the system and configurations available.

APM’s 3D level scanner ( 3D level measurement ) incorporates advanced technology for accurate and reliable measurement of bulk solids and powders in silos.

This unique device measure practically any kind of material stored in large silos.

It incorporated APM’s unique dust penetrating technology to achieve an unrivalled degree of process measurement and inventory control.

With this device it enables measurement of previously inaccessible applications. Seamlessly communicating with a plants existing ERP system providing process production and finance management with quality stock information to enable better decisions on inventory management.

The APM 3D technology is unique, unrivalled in applications where the storage silos are large.

Reliability and reduced maintenance

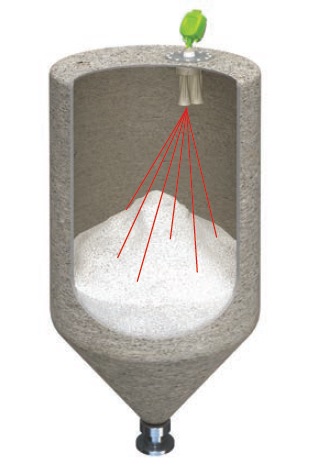

The images here show the self cleaning nature of the device. Reliability of measurement and the high accuracy is maintained using low frequency acoustic signals which are not attenuated by airborne dust in the silo.

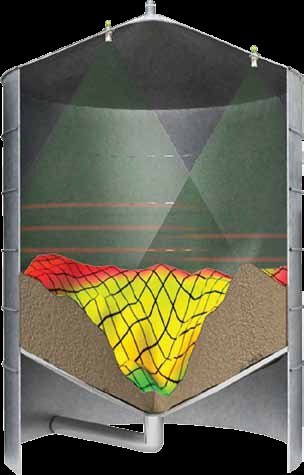

The 3D level scanner employs an array of three antennas to transmit low frequency pulses over a wide area of the material. Typically the scanners are measuring 60 level points.

The device’s digital signal processor samples and analyses the received signals from the material surface to provide very accurate measurements of the material level.

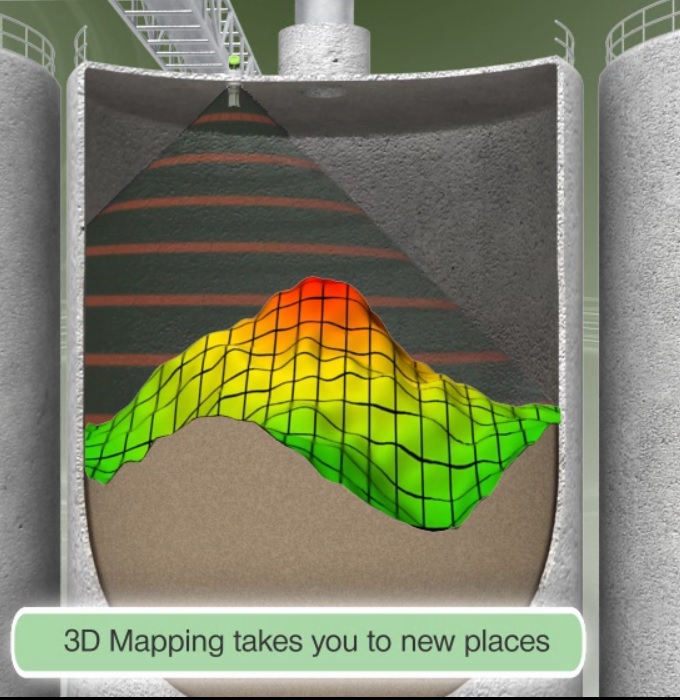

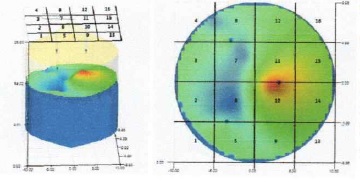

Displayed on the customers computer. The outputs from the 3D Scanner provide live data of the minimum & maximum plus average level of the material. Volume and mass units if the material bulk density is known.

A 3D graphical representation material topography is displayed. This graphic display is useful for checking the performance of the outlet system for preventative maintenance. The system is immune for effects of dust and is self cleaning in nature.

Models S, MV and MVL

Model S

Determines the average volume of the stored contents. Based on a 30 degree beam angle, Model S is ideal for small silos upto 4 meters in diameter, and for tall (up to 70 meters) and narrow silos. The model S does NOT include 3D graphical representation.

Model MV

Suitable for large diameter silos up to 10 meters in diameter. Provides minimum, maximum and average level, volume and mass of the material in storage. Includes 3D representation of the stored contents for display on a remote computer screen. This feature is useful for mapping build-up loads that form randomly over time and other irregularities. Suitable for large diameter silos up to 10 meters in diameter.

Model MVL

Multiple 3D Level scanner system for large silos above 10 meter diameter. This system is unique in providing the largest silos with accurate level, volume and mass of the material in storage. Includes 3D representation of the stored contents for display on a remote computer screen. This feature is useful for mapping build-up loads that form randomly over time and other irregularities.

MultiVision Visualisation

Monitoring of multiple silos for use by multiple users. Windows based for computer process data recording. Provides sophisticated analysis based on real-time in addition to historical logged data.

High Temperature 3D Scanner

For high temp applications such as clinker silos for maximum operating temperature of 180 C.

Section Software

View the sections in plan view, up to 99 sections, providing min, max and average section level.

Centre of Gravity

For safety and to prevent silo failure, a feature is included to provide an alarm when the stored material is excessively high against one area of the silo structure.